| Attribute | Value |

|---|---|

| Product Category: | |

| Manufacturer: | TE Connectivity |

| Manufacturer Part Number: | TE Connectivity 867471-1 |

| Housing Material: | Polyester - GF |

| Number of Rows: | 2 |

| Termination Method: | Preterminated Flying Leads |

| Pitch: | .1 in, 2.54 mm |

| Voltage: | 6000 V DC |

| Row Spacing: | .1 in, 2.54 mm |

| Contact Amperage: | 5 A |

| Number of Positions: | 6 |

| GPL: | 343 |

| Contact Mating Area Plating: | Gold |

| Shielded: | No |

| Contact Underplating Material: | Nickel |

| Panel Mount Type: | Slotted Channel for Mounting Bracket |

| Sealable: | No |

| Mating Alignment: | With |

| GPL Description: | Aerospace Defense & Marine |

| Product Code: | 4081 |

| Wire Size: | 22 AWG, .3 - .4 mm² |

| Connector Product Type: | Connector Assembly |

| ECCN: | EAR99 |

| Mating Retention: | Without |

| Cable Exit Angle: | 180° |

| Contact Retention: | With |

| Connector and Housing Type: | Receptacle |

| Wire Color: | White, Red, Green, Brown, Blue, Black |

| Part Aliases: | 867471-1 |

| SKU: | AMP867471-1 |

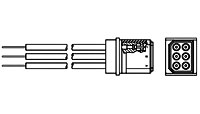

867471-1

Specifications

Detailed Description

Enhance your power connectivity with this LGH receptacle featuring preterminated flying leads for easy installation. Crafted from durable polyester GF, it guarantees reliable performance with a voltage rating of 6000 V DC. With six gold-plated contacts, each accommodating up to 5 A, it ensures efficient power transmission. Designed for aerospace, defense, and marine applications, this connector assembly is suitable for various environments. The 2.54 mm pitch and 180° cable exit angle offer flexibility in mounting and wiring. Hand solderable with lead-free processes, it complies with RoHS standards for environmental responsibility. Upgrade your power systems with this high-quality connector.

Product Change Notice

| Effective Date | Description of Change | Download | |||

|---|---|---|---|---|---|

| 05/12/2014 | P-14-010147 - Product improvement. TE Connectivity has added an additional marking process to the LGH connector product family. As an alternative to ink marking, laser marking has been added to all parts when appropriate to improve legibility and permanency. | Download | |||