| Attribute | Value |

|---|---|

| Product Category: | |

| Manufacturer: | Amphenol FCI Berg |

| Manufacturer Part Number: | Amphenol FCI Berg 10025026-10202TLF |

| Color: | Black |

| Pitch: | 1 mm |

| Mount Type: | Straddle Mount |

| Mating Cycles: | 50 cycle |

| Card Thickness: | 1.57 mm |

| Voltage Rating: | 300 VAC |

| Contact Plating: | Gold |

| Contact Material: | Copper Alloy |

| Housing Material: | Glass-Filled Nylon |

| Number of Contacts: | 98 |

| Maximum Operating Temperature: | 85 °C |

| Minimum Operating Temperature: | -55 °C |

| Series: | PCI Express® |

| SKU: | BRG10025026-10202TLF |

10025026-10202TLF

| Heilind Number: | BRG10025026-10202TLF |

| Manufacturer: | Amphenol FCI Berg |

| Manufacturer Number: | 10025026-10202TLF |

| ECAD Model: |

Specifications

Detailed Description

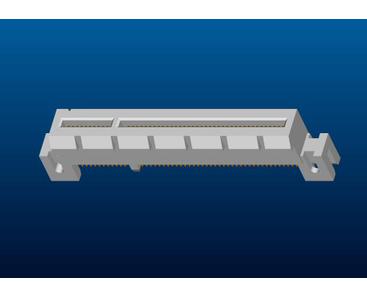

Introducing the OEM ITEM10025026-10202TLF-PCI EXPRESS, a cutting-edge PCI Express® connector designed for high-performance applications. This black connector features a durable housing made of glass-filled nylon, ensuring reliability in even the most demanding environments. With 98 contacts and a straddle mount design, it offers secure and efficient connectivity. The contacts are made of copper alloy with gold plating, providing excellent conductivity and corrosion resistance. Operating temperature ranges from -55°C to 85°C, making it suitable for a wide range of industrial settings. With a pitch of 1mm and 50 mating cycles, this connector delivers consistent performance over time. RoHS compliant and rated for 300VAC, it meets stringent safety and environmental standards. Perfect for board-to-board and card edge connections, the OEM ITEM10025026-10202TLF-PCI EXPRESS is the ideal choice for your high-speed data transfer needs.

Product Change Notice

| Effective Date | Description of Change | Download | |||

|---|---|---|---|---|---|

| 08/24/2025 | 20250224PCIE - Transfer manufacturing site . Transfer manufacturing site from Dongguan AFCI factory to Chengdu Amphenol factory for series PCIe Gen3/4/5/6 Straddle Mount series product lines, involve process: Stamping, Plating, Molding, Assembly. | Download | |||