| Attribute | Value |

|---|---|

| Product Category: | |

| Manufacturer: | Amphenol FCI Berg |

| Manufacturer Part Number: | Amphenol FCI Berg 61083-141502LF |

| Color: | Natural |

| Series: | BergStak® |

| Gender: | Male |

| Housing Material: | Glass-Filled Liquid Crystal Polymer |

| Number of Contacts: | 140 |

| Number of Rows: | 2 |

| Contact Material: | Brass |

| Contact Plating: | Gold |

| Maximum Operating Temperature: | 125 °C |

| Minimum Operating Temperature: | -40 °C |

| Pitch: | 0.8 mm |

| Mount Angle: | Straight |

| Mating Cycles: | 100 cycle |

| Flammability Rating: | UL 94V-0 |

| Current Rating: | 0.8 A |

| Voltage Rating: | 100 VAC |

| SKU: | BRG61083-141502LF |

61083-141502LF

| Heilind Number: | BRG61083-141502LF |

| Manufacturer: | Amphenol FCI Berg |

| Manufacturer Number: | 61083-141502LF |

| ECAD Model: |

Specifications

Detailed Description

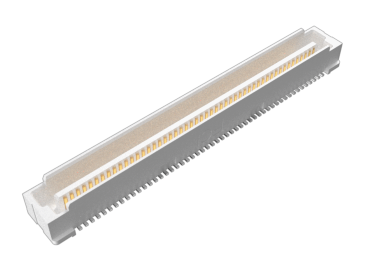

Introducing the BergStak® 61083-141502LF, a high-performance board-to-board PCB connector designed for robust and reliable connections in male gender applications. With a housing material crafted from durable glass-filled liquid crystal polymer, this connector ensures longevity and stability even in demanding environments. Featuring 140 gold-plated brass contacts arranged in two rows with a pitch of 0.8mm, it offers precise and efficient signal transmission. Operating flawlessly in temperatures ranging from -40°C to 125°C, it is suitable for a wide range of industrial applications. With a current rating of 0.8A and a voltage rating of 100VAC, this connector guarantees optimal performance. Its UL 94V-0 flammability rating underscores its safety and compliance with industry standards. Ideal for use in mezzanine and board stacking configurations, the 61083-141502LF is the perfect choice for your connectivity needs.

Product Change Notice

| Effective Date | Description of Change | Download | |||

|---|---|---|---|---|---|

| 03/30/2018 | PCN17100 - Packaging Change. To unify the carrier tapes' pitch of selected Bergstak receptacle and plug, from 16mm pitch to 12mm pitch. Refer to attached documentation for easy understanding.Reel packing qty keeps same as before, without any change for SPQ or MOQ. | Download | |||

| 04/15/2016 | PCN16002 - Packaging Change. 1. Change the existing material of carrier tape from Polystyrene clear (PS) to Polythylene terephthalate clear (PET). 2. Change existing carrier tape design to prevent deformation of solder tail of terminals. | Download | |||