| Attribute | Value |

|---|---|

| Product Category: | |

| Manufacturer: | HARTING |

| Manufacturer Part Number: | HARTING 09031426901 |

| Color: | Pebble Gray |

| Series: | DIN 41612 |

| Gender: | Male |

| Housing Material: | Glass-Filled Plastic |

| Number of Contacts: | 48 |

| Number of Rows: | 3 |

| Termination Method: | Solder |

| Contact Material: | Copper Alloy |

| Contact Plating: | Gold Over Electroless Nickel Phosphorus Over Nickel, Tin Over Nickel |

| Maximum Operating Temperature: | 125 °C |

| Minimum Operating Temperature: | -55 °C |

| Pitch: | 2.54 mm |

| Mount Angle: | Right Angle |

| Mating Cycles: | 400 cycle |

| Flammability Rating: | UL 94V-0 |

| Current Rating: | 2 A |

| Voltage Rating: | 1 kV |

| SKU: | HRT09031426901 |

09031426901

Specifications

Detailed Description

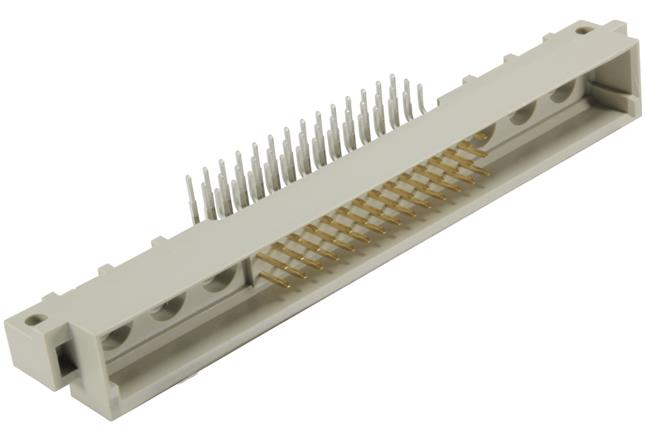

Introducing the 09031426901, a high-performance DIN 41612 Type M Male Connector designed for seamless board-to-board PCB connectivity. Crafted from durable thermoplastic resin with glass-fibre reinforcement, this connector ensures reliability in even the most demanding environments. With 48 contacts arranged in 3 rows and a pitch of 2.54mm, it allows for efficient data transfer. The solder termination method guarantees secure attachment, while the copper alloy contacts plated with tin over nickel, gold over electroless nickel phosphorus, and nickel ensure optimal conductivity. Operating smoothly in temperatures ranging from -55°C to 125°C, and with a voltage rating of 1kV, this connector is suitable for a wide range of applications. Its UL 94V-0 flammability rating and RoHS compliance further enhance its safety and environmental credentials. Upgrade your connectivity solutions with the 09031426901.

Product Change Notice

| Effective Date | Description of Change | Download | |||

|---|---|---|---|---|---|

| 06/01/2022 | PCN21-030-PMMDUS - Plating Optimization. Due to the global cost impacts to noble metals such as palladium, we would like to inform you of plating optimizations that will be made to our DIN BC product portfolio. Part of this optimization is the implementation of nickel-phosphor plating – a surface that has been tested in the industry for decades. | Download | |||