| Attribute | Value |

|---|---|

| Product Category: | |

| Manufacturer: | HARTING |

| Manufacturer Part Number: | HARTING 09233486951 |

| Color: | Pebble Gray |

| Series: | DIN 41612 |

| Gender: | Male |

| Housing Material: | Glass-Filled Plastic |

| Number of Contacts: | 48 |

| Number of Rows: | 3 |

| Termination Method: | Solder |

| Contact Material: | Copper Alloy |

| Contact Plating: | Gold Over Electroless Nickel Phosphorus Over Nickel, Tin Over Nickel |

| Maximum Operating Temperature: | 125 °C |

| Minimum Operating Temperature: | -55 °C |

| Pitch: | 2.54 mm |

| Mount Angle: | Right Angle |

| Mating Cycles: | 400 cycle |

| Flammability Rating: | UL 94V-0 |

| Current Rating: | 2 A |

| Voltage Rating: | 1 kV |

| SKU: | HRT09233486951 |

09233486951

Specifications

Detailed Description

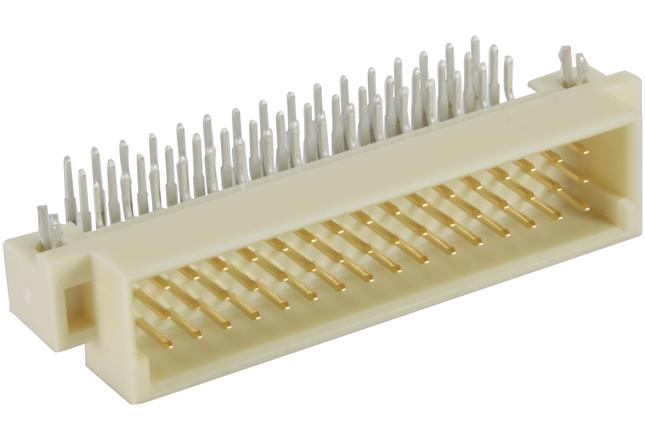

Introducing the DIN 41612 Type 2C Connector, a vital component for seamless motherboard to daughtercard, extender card, and PCB to cable connections. This male connector boasts a durable construction of thermoplastic resin with glass-fibre filling, ensuring reliable performance in any application. With a pebble gray housing made of glass-filled plastic, it offers not just functionality but also a sleek aesthetic. Featuring 48 contacts in 3 rows, terminated via solder for secure attachment, and crafted from copper alloy with tin, nickel, and gold plating for enhanced conductivity and corrosion resistance. Its wide operating temperature range of -55°C to 125°C, along with a voltage rating of 1 kV, guarantees suitability for diverse environments. With a pitch of 2.54 mm and right-angle mount, it facilitates efficient board-to-board connections. UL 94V-0 rated for safety, and with a robust design capable of 400 mating cycles, this connector is a dependable solution for your connectivity needs.

Product Change Notice

| Effective Date | Description of Change | Download | |||

|---|---|---|---|---|---|

| 06/01/2022 | PCN21-030-PMMDUS - Plating Optimization. Due to the global cost impacts to noble metals such as palladium, we would like to inform you of plating optimizations that will be made to our DIN BC product portfolio. Part of this optimization is the implementation of nickel-phosphor plating – a surface that has been tested in the industry for decades. | Download | |||