| Attribute | Value |

|---|---|

| Product Category: | |

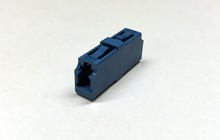

| Manufacturer: | Molex |

| Manufacturer Part Number: | Molex 106125-0100 |

| Color: | Blue |

| Series: | 106125 - LC |

| Connector Type: | LC |

| Gender: | Female |

| Housing Material: | Polymer |

| Number of Ports: | 2 |

| Orientation: | Straight |

| Shuttering: | No Shutter |

| Component Type: | Standard |

| Panel Mount: | With |

| Shielded: | No |

| Ferrule Material: | Metal |

| Mounting Hardware Type: | Snap |

| Part Aliases: | 1061250100 861250100 |

| SKU: | MOL106125-0100 |

106125-0100

Specifications

Detailed Description

Enhance connectivity with this LC Adapter, featuring a sleek blue body and a durable metal alignment sleeve for precision. Designed for duplex configurations, it offers seamless integration with fiber optic systems. The snap mount style ensures easy installation, while the polymer housing guarantees long-lasting performance. With two ports and a straight orientation, it provides versatile connectivity options. Perfect for standard panel mounting, this adapter is essential for efficient data transmission in various networking environments. Rest assured of its quality, as it is RoHS compliant, making it a reliable choice for your networking needs.

Product Change Notice

| Effective Date | Description of Change | Download | |||

|---|---|---|---|---|---|

| 07/03/2015 | GCM 10699658 - Change Construction Or Material. This letter is to inform you that Molex has recently received a declaration of Force Majeure from a plastic resin supplier for one of the plastic resins used for making dust caps for our connectors. A stabilizer additive used in this plastic resin is nearly obsolete globally. This declaration takes effect immediately. Molex has tested and qualified an alternate resin from the same resin manufacturer. Due to the urgency of the situation, and rather than limiting customer orders, Molex has chosen to keep continuity of supply and provide customers with parts manufactured in the alternate material. Molex molding processes are being closely monitored to ensure there are no changes or abnormal variation. Production control plans, inspection, and in-process testing are being followed closely to ensure all requirements are being met. Internal validation test plans are developed and executed on key products to ensure compliance to specifications. | Download | |||