| Attribute | Value |

|---|---|

| Product Category: | |

| Manufacturer: | Molex |

| Manufacturer Part Number: | Molex 39543-0208 |

| Series: | 39543 - ESE - Eurostyle Fixed Mount |

| Amperage: | 10 A |

| Connector Type: | ESE, Eurostyle Fixed Mount |

| Number of Rows: | 1 |

| Mount Type: | No |

| Pitch: | 5 mm |

| Voltage: | 300 V |

| Orientation: | 45° Angle |

| Component Type: | One Piece |

| Tail Length: | 3 mm |

| Operating Temperature Range: | -40 - 105 °C |

| Number of Contacts Loaded: | 8 |

| PCB Thickness (Recommended): | 2 mm |

| Wire Size: | 14 AWG, 16 AWG, 18 AWG, 20 AWG, 22 AWG, 24 AWG, .2 - 2.08 mm² |

| UL Agency Certification: | E48521 |

| Maximum Solder Process Temperature: | 260 °C |

| Lead Free Process Capability: | WAVE |

| Duration at Max. Process Temperature (seconds): | 005 |

| Max. Cycles at Max. Process Temperature: | 135 |

| Termination Pitch: | 5 mm |

| Lock to Mating Part: | No |

| Stackable: | No |

| Part Aliases: | 0395430208 |

| SKU: | MOL39543-0208 |

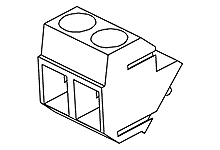

39543-0208

Specifications

Detailed Description

Introducing the ESE Eurostyle Fixed Mount Terminal Block, featuring a 45° Angle orientation for efficient connectivity. With a 10A amperage and 300V voltage rating, it ensures reliable performance. This one-piece connector has 8 contacts loaded in a single row, with a 5mm pitch for easy PCB mounting. The tail length of 3mm accommodates various wire sizes, from 24AWG to 18AWG, and 0.2-2.08mm². Operating in a wide temperature range (-40 to 105°C), it is suitable for diverse applications. Certified by UL (E48521) and compliant with RoHS, it upholds quality and environmental standards. With a lead-free process capability, it withstands wave soldering at 260°C. Designed for durability, it can endure 135 cycles at the maximum process temperature, making it a dependable choice for your PCB terminal block needs.

Product Change Notice

| Effective Date | Description of Change | Download | |||

|---|---|---|---|---|---|

| 11/01/2015 | GCM 10721686 - Change In Packaging Specifications. Molex is changing the tray packaging from Polystyrene (White) to PET (Clear). The reason is cosmetic as the Polystyrene trays have a tendency to crack on the edges. The PET trays are more flexible and less susceptible to tearing. Molex will make is a running change. | Download | |||