| Attribute | Value |

|---|---|

| Product Category: | |

| Manufacturer: | Molex |

| Manufacturer Part Number: | Molex 39543-3014 |

| Series: | 39543 - ESE - Eurostyle Fixed Mount |

| Amperage: | 15 A |

| Connector Type: | ESE, Eurostyle Fixed Mount |

| Number of Rows: | 1 |

| Mount Type: | No |

| Body Orientation: | Straight |

| Pitch: | 5 mm |

| Voltage: | 300 V |

| Orientation: | Vertical |

| Component Type: | One Piece |

| Tail Length: | 3 mm |

| Operating Temperature Range: | -40 - 105 °C |

| Number of Contacts Loaded: | 14 |

| PCB Thickness (Recommended): | 2 mm |

| Wire Size: | 14 AWG, 16 AWG, 18 AWG, 20 AWG, 22 AWG, .33 - 2.08 mm² |

| UL Agency Certification: | E48521 |

| Maximum Solder Process Temperature: | 260 °C |

| Lead Free Process Capability: | WAVE |

| Duration at Max. Process Temperature (seconds): | 005 |

| Max. Cycles at Max. Process Temperature: | 135 |

| Termination Pitch: | 5 mm |

| Lock to Mating Part: | No |

| Stackable: | No |

| Part Aliases: | 0395433014 |

| SKU: | MOL39543-3014 |

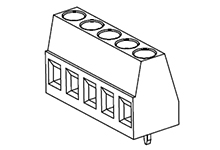

39543-3014

Specifications

Detailed Description

Introducing the ESE Eurostyle Fixed Mount Terminal Block, a reliable and versatile solution for your connectivity needs. With a 15A amperage rating and 300V voltage capacity, this straight body orientation connector is ideal for various applications. Featuring one row and 14 contacts, it offers efficient PCB mounting with a 5mm pitch and 3mm tail length. Operating in a wide temperature range of -40 to 105°C, it ensures durability in diverse environments. Compatible with wire sizes ranging from 22 to 14 AWG, it provides flexibility in connection options. Certified for quality and safety, it meets E48521 standards and is lead-free, with a maximum solder process temperature of 260°C. Whether for industrial or commercial use, this terminal block guarantees secure and efficient connections.

Product Change Notice

| Effective Date | Description of Change | Download | |||

|---|---|---|---|---|---|

| 11/01/2015 | GCM 10721686 - Change In Packaging Specifications. Molex is changing the tray packaging from Polystyrene (White) to PET (Clear). The reason is cosmetic as the Polystyrene trays have a tendency to crack on the edges. The PET trays are more flexible and less susceptible to tearing. Molex will make is a running change. | Download | |||