| Attribute | Value |

|---|---|

| Product Category: | |

| Manufacturer: | Molex |

| Manufacturer Part Number: | Molex 502430-2230 |

| Color: | Black |

| Series: | 502430 |

| Amperage: | .3 A |

| Connector Type: | SlimStack |

| Number of Contacts: | 22 |

| Number of Rows: | 2 |

| Termination Method: | Surface Mount |

| Contact Material: | Phosphor Bronze |

| Body Orientation: | Straight |

| Pitch: | 4 mm |

| Voltage: | 50 V AC/DC |

| Orientation: | Vertical |

| Operating Temperature Range: | -20 - 85 °C |

| Contact Mating Area Plating: | Gold |

| Number of Contacts Loaded: | 22 |

| Mating Cycles: | 30 |

| PCB Locator: | No |

| PCB Retention: | Yes |

| Polarized to PCB: | No |

| Polarized to Mate: | No |

| Connector System: | Board to Board |

| Contact Termination Plating: | Gold |

| Glow Wire Capable: | No |

| Mated Height: | 1 mm |

| Mated Width: | 2.6 mm |

| Breakaway: | No |

| Product Name: | SlimStack |

| Part Aliases: | 5024302230 |

| SKU: | MOL502430-2230 |

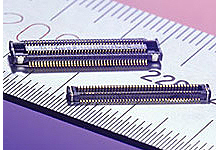

502430-2230

Specifications

Detailed Description

Enhance your PCB connectivity with our Black SlimStack Connector, featuring a sleek design and high-performance capabilities. With a low amperage of .3 A and 22 contacts spread across 2 rows, it offers efficient power distribution. The surface mount termination method and phosphor bronze contact material ensure secure and reliable connections. Operating at a voltage of 50 V AC/DC and with a wide temperature range of -20 to 85 °C, it is suitable for various environments. The gold plating in the contact mating area guarantees optimal conductivity, while the compact pitch of .4 mm saves space on your board. RoHS compliant and with a mated height of 1 mm, this connector is a durable and eco-friendly choice for your electronic projects. Elevate your PCB designs with our high-quality SlimStack Connector.

Product Change Notice

| Effective Date | Description of Change | Download | |||

|---|---|---|---|---|---|

| 04/15/2023 | 513305 - Molex analyzed the plating process of terminal of 0.4BB 502430 series. Manufacturing Process Change. The result shows that over-plating gold at non-functional positions causes waste of gold and tool/jig management costs. So the decision for removing plating gold of these positions was made. The qualification will be conducted to ensure there is no change in product specification. | Download | |||