| Attribute | Value |

|---|---|

| Product Category: | |

| Manufacturer: | Molex |

| Manufacturer Part Number: | Molex 75640-5003 |

| Color: | Black, Clear (Blue Tint) |

| Series: | 75640 - SFP |

| Amperage: | .5 A |

| Connector Type: | SFP |

| Number of Contacts: | 40 |

| Termination Method: | Through Hole - Compliant Pin |

| Contact Material: | High Performance Alloy (HPA) |

| Contact Plating: | Gold |

| Body Orientation: | Right Angle |

| Pitch: | 8 mm |

| Voltage: | 30 V |

| Shield Type: | EMI Fingers |

| Material: | Polycarbonate, Thermoplastic |

| Orientation: | Right Angle |

| Component Type: | Receptacle |

| Tail Length: | 3.05 mm |

| Packaging: | Tray |

| Operating Temperature Range: | -40 - 85 °C |

| Contact Mating Area Plating: | Gold |

| Contact Mating Area Plating Thickness: | .762 µm |

| Number of Contacts Loaded: | 40 |

| Mating Cycles: | 200 |

| PCB Locator: | Yes |

| Shielded: | Yes |

| PCB Retention: | Yes |

| Polarized to PCB: | Yes |

| Contact Termination Plating Thickness: | .762 µm |

| Polarized to Mate: | Yes |

| PCB Thickness (Recommended): | 2.4 mm |

| Supplier Product Group: | High Speed Cage & Connector Assemblies |

| Connector System: | Module to Board |

| CSA Agency Certification: | LR19980 |

| UL Agency Certification: | E29179 |

| Contact Termination Plating: | Tin |

| Termination Pitch: | .8 mm |

| Lock to Mating Part: | Yes |

| Surface Mount Compatible: | No |

| Waterproof Dustproof: | No |

| Material Flammability Standard: | 94V-0 |

| Part Aliases: | 0756405003 |

| SKU: | MOL75640-5003 |

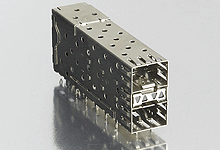

75640-5003

| Heilind Number: | MOL75640-5003 |

| Manufacturer: | Molex |

| Manufacturer Number: | 75640-5003 |

| Datasheet: | Application Specification |

| ECAD Model: |

Description:

Small Form-factor Pluggable (SFP) Stacked 2-by-1 Multi-Port Connector with 2 Outer Lightpipes, with Press-fit PC Tails, 40 Circuits, Lead-Free

More >>Specifications

Detailed Description

Enhance connectivity with our Small Form-factor Pluggable (SFP) Stacked 2-by-1 Multi-Port Connector, featuring 40 circuits for efficient data transmission. Crafted with high-performance alloy contacts plated in gold, this connector ensures reliable signal transfer, while its right-angle body orientation and press-fit PC tails offer ease of installation. The inclusion of EMI fingers and shielded construction guarantees secure connections, meeting stringent industry standards. With a wide operating temperature range and RoHS compliance, this connector is suitable for diverse applications, from telecommunications to industrial automation. Elevate your connectivity solutions with this versatile and durable component.

Product Change Notice

| Effective Date | Description of Change | Download | |||

|---|---|---|---|---|---|

| 06/04/2026 | 517622 - Packaging Method/Quantity Changing. will undergo changes for PU foam to EPE Foam. No changes will be made to product as part of this change. | Download | |||

| 03/08/2024 | 514107 - Equipment Transfer, Production Transfer or Rearrangement. In order to increase the Molex manufacturing footprint, Molex will transfer the existing assembly lines to a local qualified assembly vendor. | Download | |||

| 03/30/2023 | 512623 - Packaging Method/QTY changing. Molex will remove inner box and PE Endcap foam.it is only package improvement, SPQ&MOQ are same ,no any change to product dimension, function and fit. | Download | |||

| 09/20/2022 | 512191 - Packaging Method/Quantity Changing. Molex will replace the top locked cartons with normal standard cartons. Carton size / packaging quantity and packaging materials remain unchanged. No changes will be made to the part design and will not affect the use or disposal of inventory. | Download | |||

| 12/15/2015 | GCM 10715564 - Supplier Changes To Raw Material. This notification is to advise you of a change in supplier for the Nickel Silver base material used to make some components in some of Molex's products. The biggest users are cage components. Only the supplier will be changing, the type of the material will stay the same so there will be no impact to the form, fit, or function of the part. This change is needed because the current supplier is no longer offering the base material being used today. This will be a running change and will not affect the connector portion of the finished part. | Download | |||