| Attribute | Value |

|---|---|

| Product Category: | |

| Manufacturer: | Molex |

| Manufacturer Part Number: | Molex 85727-1003 |

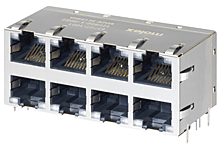

| Series: | 85727 - Magnetic Jack - Modular Jack 8/8 - RJ45 |

| Amperage: | 1.5 A |

| Connector Type: | Magnetic Jack, Modular Jack 8/8, RJ45 |

| Gender: | Female |

| Termination Method: | Through Hole |

| Contact Material: | Brass |

| Contact Plating: | Gold |

| Body Orientation: | Right Angle |

| Pitch: | 1.02 mm |

| Voltage: | 125 V AC/DC |

| Material: | PBT |

| Number of Ports: | 8 |

| Orientation: | 90° Angle |

| Component Type: | PCB Jack |

| Cable Type: | CAT 5, CAT 6 |

| Packaging: | Tray |

| Operating Temperature Range: | 0 - 70 °C |

| Contact Mating Area Plating: | Gold |

| Contact Mating Area Plating Thickness: | .762 µm |

| Ground to Panel / PCB: | Yes |

| Mating Cycles: | 750 |

| PCB Thickness (Recommended): | 2.2 mm |

| Contact Termination Plating: | Tin |

| Surface Mount Compatible: | No |

| Non Magnetic: | Yes |

| Power Over Ethernet (PoE): | Non-PoE |

| Part Aliases: | 0857271003 |

| SKU: | MOL85727-1003 |

85727-1003

Specifications

Detailed Description

Enhance your network connectivity with our Gigabit Magnetic Jack, designed for seamless integration into your system. Featuring a durable construction with green and yellow LED indicators, this RJ45 Modular Jack 8/8 ensures reliable performance. With a 1.5A amperage and 125V AC/DC voltage rating, it's suitable for high-speed data transmission. The right-angle body orientation and through-hole termination method make it easy to install on your PCB. RoHS compliant and non-PoE, this jack is ideal for CAT 5 and CAT 6 cables in various applications. Trust in its gold-plated brass contacts and 90° angle orientation for efficient signal transmission, meeting your connectivity needs with precision.

Product Change Notice

| Effective Date | Description of Change | Download | |||

|---|---|---|---|---|---|

| 05/15/2023 | 512898 - Change Supplier. The purpose of this notice is to inform you that the resin manufacturer will stop producing this material in its existing factory in Thailand. The resin manufacturer requires to change the source of materials to Nansha Factory in China. | Download | |||

| 09/10/2016 | 501082 - Change to Product. This letter is to inform you that changes are being made to the part(s) identified in this Notice. The change will affect the fit, form, function or appearance of the parts. Or, it may result in a change to the specification. | Download | |||

| 09/09/2016 | 501187 - Manufacturing Process Change Molex and Suppliers. This letter is to inform you that the manufacturing process for the part(s) identified in this notice is changing. No changes will be made to the product as a result of this process change. | Download | |||

| 12/25/2015 | GCM 10738792 - Manufacturing Process Change. Because the Magbox wire supplier have closed the old production line and moved the production line to the new location and will start to resume the production. Suntek move the tooling/equipment/Documents for the new production line. No impact on the functional, cosmetic and fit issue; this change will be implement once finish the internal qualification. | Download | |||

| 11/23/2015 | GCM 10729131 - Supplier Change. To improve the delivery Consolidate the sourcing for the solder bar( component part number 172007609), Molex DG is going to add the new sourcing which already using for other existing projects for the solder bar. There is not any impact for the function and assembly process with the parts from new sourcing. | Download | |||

| 11/13/2015 | GCM 10726660 - Supplier Change. This change is to notify on the change of magbox wire vendor due to cessation of supply from the current approved vendor. There will be no impact from this change, to the fit, form or function of the product. This change has been caused by the closure of the current wire supplier. The change will be implemented on a phased basis as old wire stocks are depleted. Trace-ability on the change will be ensured through connector date code tracking. | Download | |||

| 03/01/2015 | GCM 10672659 - Manufacturing Process Change. The purpose of this process change is to reduce the risk of damage to the magnetics caused by ultrasonic cleaning. A new non-clean process has been developed and proven that removes the need for any cleaning during the magnetics/transformer construction process. This improvement was developed after a study indicated that ultrasonic cleaning has the ability to damage magnetic wire. This change will be phased in by product series during the first half of 2015. | Download | |||