| Attribute | Value |

|---|---|

| Product Category: | |

| Manufacturer: | TE Connectivity |

| Manufacturer Part Number: | TE Connectivity 5-103634-3 |

| Series: | AMPMODU MTE |

| Amperage: | 3 A |

| Housing Material: | Thermoplastic |

| Number of Contacts: | 4 |

| Number of Rows: | 1 |

| Termination Method: | Crimp, Insulation Displacement Crimp (IDC), Through Hole - Solder |

| Contact Material: | Brass |

| Pitch: | .1 in, 2.54 mm |

| Contact Type: | Pin |

| Strain Relief: | No Strain Relief |

| Row Spacing: | .1 in, 2.54 mm |

| Package Quantity: | 42 |

| Contact Amperage: | 3 A |

| Number of Positions: | 4 |

| Housing Color: | Black |

| Mount Orientation: | Right Angle |

| Insulation Resistance: | 5000 MΩ |

| GPL: | 296 |

| Packaging: | Tube, Tube/Box |

| Operating Temperature Range: | -65 - 105 °C |

| Circuit Application: | Signal |

| Contact Mating Area Plating: | Tin |

| Contact Mating Area Plating Thickness: | 100 µin, 2.54 µm |

| PCB Retention: | Without |

| PCB Contact Termination Area Plating: | Tin |

| Connector Height: | 13.59 mm, .535 in |

| GPL Description: | Industrial |

| Connector and Contact Terminate To: | Printed Circuit Board |

| Product Code: | 6257 |

| Connector Length: | 12.7 mm, .5 in |

| ECCN: | EAR99 |

| Dielectric Withstanding Voltage: | 600 V |

| Termination Resistance: | 15 mΩ |

| Contact Shape: | Square |

| PCB Contact Termination Area Plating Finish: | Matte |

| Mating Retention: | With |

| PCB Mount Alignment: | Without |

| Termination Post Tail Length: | .13 in, 3.3 mm |

| Header Type: | Shrouded |

| Connector Assembly Type: | PCB Mount Header |

| PCB Contact Termination Area Plating Thickness: | 100 µin, 2.54 µm |

| Contact Mating Area Length: | .23 in, 5.84 mm |

| Contact Retention: | With |

| Contact Retention Type in Housing: | Locking Lance |

| Standards Met: | CSA LR7189 UL E28476 |

| Material Flammability Standard: | UL 94V-0 |

| Part Aliases: | 5-103634-3 |

| SKU: | AMP5-103634-3 |

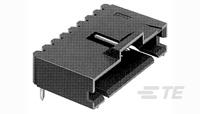

5-103634-3

Specifications

Detailed Description

Introducing the AMPMODU MTE series PCB Pin Header, a versatile and reliable connectivity solution for your electronic applications. With a housing made of flame-retardant thermoplastic in sleek black, this header is designed to meet stringent standards for safety and performance, including CSA and UL certifications. Featuring four contacts arranged in a single row with a pitch of 2.54mm (.1 in), it offers efficient signal transmission. The contacts, made of brass with tin plating, ensure optimal conductivity and durability. With various termination methods available – crimp, through hole-solder, and IDC – installation is convenient and secure. The right-angle mount orientation and compact size make it ideal for space-constrained PCB layouts. Whether for industrial or commercial use, this header guarantees reliable performance in a wide temperature range. RoHS compliant and with excellent dielectric properties, it meets international environmental and safety standards. Complete with 42 units in a tube/package, the AMPMODU MTE series PCB Pin Header is the perfect choice for your connectivity needs.

For Use With

| Product | Part # | Description | Stock |

|---|---|---|---|

| TE Connectivity 5-103956-3 |  | |

| TE Connectivity 5-103959-3 |  | |

| TE Connectivity 5-103971-3 |  |

Product Change Notice

| Effective Date | Description of Change | Download | |||

|---|---|---|---|---|---|

| 12/13/2021 | P-21-020887 - Manufacturing location change. In order to better align TE s manufacturing footprint to customer region of consumption, one of the assembly machines that make the AMPMODU MTE Assemblies, will be moved from the Hermosillo, Senora, Mexico plant to our Suzhou, China plant. For customers who are ordering the following AMPMODU MTE assemblies, with final consumption in the Europe or Asia-Pacific countries, the manufacturing location will change from our Hermosillo, Senora, Mexico plant to our Suzhou, China plant. These orders will be fulfilled by our Suzhou, China Plant. For all other customers whose final consumption is in the remaining global regions, and who order the following AMPMODU MTE assemblies, the manufacturing location will remain in our Hermosillo, Senora, Mexico plant. | Download | |||

| 08/03/2021 | E-21-005720-C - PCN will not clear by the time the system that the EC and PCN were written in is decommissioned. Hence, this ECR and PCN is being cancelled in the old system and will be rewritten in the New EC system. | Download | |||

| 06/30/2021 | E-21-005720 - Product Improvement. Addendum to PCN E-20-000624 (ATTACHED). one of the changes noted in PCN E-20-000624 is not being Implemented due to financial implications the tooling change shown in the attached MTE shrouded header tooling change file is being made to be at the molder's discretion. Some parts may have this recessed area, some might not. there is no performance difference between the parts with the recession and the parts without the recession. | Download | |||

| 05/29/2020 | E-20-000624 - Product Improvement. To provide flexibility to our manufacturing processes, we are allowing the manufacturing plants, when possible, to utilize regrind resin, up to the allowable limit specified on the UL Yellow Card, in the molding process. Adding feature at latch to increase mold efficiency. | Download | |||