HARTING Connectors for Energy & Power Systems

HARTING supports the energy and power sector—including renewable integration, large-scale energy storage, and data center infrastructure—by providing robust, high-current, modular battery connectors and pre-tested cabling solutions that speed installation, simplify servicing, and reduce operating costs. Its connectivity solutions are engineered for safe, error-proof use in demanding environments (including restricted-access “blind mating” scenarios) and meet relevant UL requirements for stationary energy storage. As part of the broader data center infrastructure—which encompasses servers, storage, networking equipment, PDUs, cooling, and security—HARTING’s modular interfaces allow power, data, and other media to be combined in a single scalable connection architecture. This helps users efficiently deploy storage assets, connect to downstream systems, and adapt as capacity grows, from grid-level installations to data centers and mobile or second-life battery applications. Durable, fully tested assemblies further enhance reliability under harsh conditions, supporting the performance, scalability, and efficiency required by modern data center operations.[/caption]

HARTING supports the energy and power sector—including renewable integration, large-scale energy storage, and data center infrastructure—by providing robust, high-current, modular battery connectors and pre-tested cabling solutions that speed installation, simplify servicing, and reduce operating costs. Its connectivity solutions are engineered for safe, error-proof use in demanding environments (including restricted-access “blind mating” scenarios) and meet relevant UL requirements for stationary energy storage. As part of the broader data center infrastructure—which encompasses servers, storage, networking equipment, PDUs, cooling, and security—HARTING’s modular interfaces allow power, data, and other media to be combined in a single scalable connection architecture. This helps users efficiently deploy storage assets, connect to downstream systems, and adapt as capacity grows, from grid-level installations to data centers and mobile or second-life battery applications. Durable, fully tested assemblies further enhance reliability under harsh conditions, supporting the performance, scalability, and efficiency required by modern data center operations.[/caption]

- Energy Grid Connectivity

- Rack Power Distribution Systems – PowerShelf, Busbar & Tap Off Box, Power Whips, PDUs

- Building Management Systems – BMS Cabinets, Lighting & HVAC Systems

- Networking – Data Connections

- Harsh Environmental Conditions- Heavy-duty, sealed, EMI-protected connectors ensure reliable power and data transmission in extreme weather, vibration, and contamination.

- Grid adaptation for renewables- Modular, plug-and-play systems simplify integration of solar, wind, and decentralized generation into existing infrastructure

- Hydrogen energy processes- High-temperature, ATEX-rated, and modular connectors provide safe, reliable performance across electrolysis, storage, and distribution

Battery energy storage systems- Han® S series connectors enable safe, quick, high-voltage connections for modular battery storage.

Offshore and industrial sites-Corrosion-resistant, rugged connectors maintain performance in saltwater, humidity, and heavy mechanical stress.

- High Performance Transformer Connectors HPTC

- Han Modular Heavy Duty Connectors

- Metric Circular Connectors

- Fiber Optic Cables

- Han-Eco

- Han HPR Sing Pole Connectors

- Han S

Featured Product Solutions

Han® S is the first special high-current battery connector that meets the relevant UL and for stationary energy storage systems. Among others, it fulfils the requirements of UL 4128 for connectors in electrochemical battery system applications, UL 1973 for batteries in stationary applications, for emergency power supply for vehicles and in light rail applications, and UL 9540 for energy storage systems and accessories.Contacts for currents up to 200 A and 1500 V can be accommodated in this compact and flexible housing. The bulkhead mounted housings in this series can be rotated flexibly by 360 degrees. The locking together of the male and female housings is intuitive.

Han® S is the first special high-current battery connector that meets the relevant UL and for stationary energy storage systems. Among others, it fulfils the requirements of UL 4128 for connectors in electrochemical battery system applications, UL 1973 for batteries in stationary applications, for emergency power supply for vehicles and in light rail applications, and UL 9540 for energy storage systems and accessories.Contacts for currents up to 200 A and 1500 V can be accommodated in this compact and flexible housing. The bulkhead mounted housings in this series can be rotated flexibly by 360 degrees. The locking together of the male and female housings is intuitive.

Features & Benefits:

- Recessed and insulated conductive elements provides optimized protection at both mating faces of contacts

- Visual color and physical keying of connectors eliminates incorrect installation with quick visual indicator of + or – pole

- Straight attachment housing with angled plug that has integrated pivotable elements

- Can be rotated 360 degrees, including when installed

Specially developed for railway transformer applications, the Han® HPR HPTC series withstands mechanical impacts, water, oil, sunlight, and ozone. Its robust, fully shielded design ensures easy handling, minimal components, and maximum security. Featuring a touch-proof insulating body, integrated cable gland, and unique all-around metallic contact, it safely collects and discharges residual currents for reliable performance in harsh environments. The Han® HPR HPTC also simplifies installation. No shrinking or taping is required to set up transformer connections and the interfaces are quick to prepare: Crimp the contacts, insert the insulating body with shielding into the housing, close the cover – and the cable side is ready.

Specially developed for railway transformer applications, the Han® HPR HPTC series withstands mechanical impacts, water, oil, sunlight, and ozone. Its robust, fully shielded design ensures easy handling, minimal components, and maximum security. Featuring a touch-proof insulating body, integrated cable gland, and unique all-around metallic contact, it safely collects and discharges residual currents for reliable performance in harsh environments. The Han® HPR HPTC also simplifies installation. No shrinking or taping is required to set up transformer connections and the interfaces are quick to prepare: Crimp the contacts, insert the insulating body with shielding into the housing, close the cover – and the cable side is ready.

Features & Benefits:

- Longer lifetime due to Han® HPR standard metal hoods and housings for harsh environments

- Time savings due to easy installation and shielding without shrinking or taping

- Cost savings due to minimum inventory needed based on efficient coding system

- Secure solution according to relevant railway standards (EN 50467, EN 50124-1, EN 61373, EN 45545, EN 60137)

- Shock- and vibration proofed system

The HARTING Han HPR Single Pole Connectors are robust, high-current, quick-disconnect connectors rated up to 800 A and 4000 V, featuring a durable die-cast aluminum housing with IP68/IP69 protection, 36 keying configurations for foolproof installation, and compatibility with HC Modular contacts and HPR VarioShell housings—ideal for demanding environments like railways and renewable energy systems.

The HARTING Han HPR Single Pole Connectors are robust, high-current, quick-disconnect connectors rated up to 800 A and 4000 V, featuring a durable die-cast aluminum housing with IP68/IP69 protection, 36 keying configurations for foolproof installation, and compatibility with HC Modular contacts and HPR VarioShell housings—ideal for demanding environments like railways and renewable energy systems.

Features & Benefits:

- High Power & Voltage: Supports cable currents up to 800 A and AC/DC voltages up to 4000 V

- Durable Design: Comes in a die-cast aluminum enclosure rated IP68/IP69, built to withstand shock, vibration, and severe environmental conditions

- Excellent Polarization & EMI Protection: Offers 2 coding cavities with 36 different keying choices, plus a poka-yoke design with recessed O-ring and full 360° metal shielding for EMI control

- Modular & Compatible: Works with existing HC Modular contacts and can be enhanced using HPR VarioShell housings for flexible configurations

- Targeted Applications: Optimized for power generation, energy industries, non-auto transportation—including railway systems, wind turbines, inverters, traction motors, & power distribution hubs

- Space- and Weight-Efficient: Single-core structure helps reduce both bulk and mass

The Harting Han-Eco® product line an easy to assemble, lighter weight robust connector system. The housing is made from high-performance plastic and stands up to all external influences. It is offered in an indoor and outdoor version. The outdoor version uses FPM sealing with high environmental resistance. The compact design permits higher contact density. Easy to assemble even in difficult to reach locations. The 10 amp and 16 amp versions expand the Han-Eco series portfolio.

The Harting Han-Eco® product line an easy to assemble, lighter weight robust connector system. The housing is made from high-performance plastic and stands up to all external influences. It is offered in an indoor and outdoor version. The outdoor version uses FPM sealing with high environmental resistance. The compact design permits higher contact density. Easy to assemble even in difficult to reach locations. The 10 amp and 16 amp versions expand the Han-Eco series portfolio.

Features & Benefits:

- Installation of inserts from mating side and rear side of the cabinet

- Mating compatibility to metal hood/housings of 10A & 16A

- Same panel cut- outs as metal bulkhead

- Flexible in size of cable glands (M20 & M25)

–

Han-Eco B Series

HARTING’s Han-Eco® B series is an expansive series of thermoplastic, economical, and corrosion-resistant hoods & housings.

The key feature of the Han-Eco B series is the option of rear mounting when assembling a switch cabinet. In order to assemble the wired insert into the bulkhead housing, the wired insert no longer needs to be fished back though the switch cabinet’s cutout from the front side. Instead, a pre-assembled wiring harness can easily be snapped into the already mounted bulkhead housing from the inside of the switch cabinet – rearward. This option simplifies the assembly and also optimizes the assembly floor by allowing the wire harness to be a stocked item or even assembled offsite; thus saving time and cost. Switch cabinet units and cable harnesses can now be pre-assembled separately. A better division of labor is possible and, if necessary, processes can even be outsourced. In addition, the Han-Eco B Series is fully compatible with Han® metal connectors, extending the possibility to add an economical solution to existing applications. The Han-Eco B series is also able to use any HARTING inserts, allowing any application in industrial connectivity to take advantage of this economical solution.

–

Discover More Han-Eco Products:

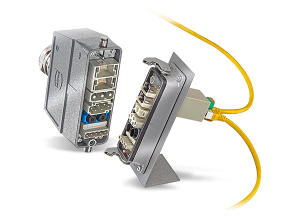

Rectangular connectors are the perfect base to get used of the advantages of modular connectors, thus offering to integrate power, signal, data and even compressed air into a single unique interface. As the inventor of the modular industrial connector, HARTING is offering the market standard for modular connectors – the Han-Modular® series. Users can optimally design connectors to supply machinery and equipment. This is made possible by combining individual modules for different transmission media in standard-sized industrial connector housings. Han-Modular® offers easy-to-handle, highly flexible solutions with a small footprint and versatile functionality.

Rectangular connectors are the perfect base to get used of the advantages of modular connectors, thus offering to integrate power, signal, data and even compressed air into a single unique interface. As the inventor of the modular industrial connector, HARTING is offering the market standard for modular connectors – the Han-Modular® series. Users can optimally design connectors to supply machinery and equipment. This is made possible by combining individual modules for different transmission media in standard-sized industrial connector housings. Han-Modular® offers easy-to-handle, highly flexible solutions with a small footprint and versatile functionality.

Introduced in 2022, Han-Modular® Domino Modules open up new possibilities for optimisation, including space and weight savings of up to 50%, thus reducing the CO2 footprint. Han-Modular® is HARTING’s highly flexible, configurable rectangular connector system—built from a combinable assortment of modules, frames, hoods/housings, and accessories. Designed to offer wide-ranging application coverage (signal, power, data, high current, etc.), it supports multiple sizes, IP protection levels, locking mechanisms, and cable entry styles. In short: it’s a robust modular portfolio tailored to meet diverse industrial connector needs.

Features & Benefits:

- Integration of multiple connectors into a single unit

- Future-proof thanks to flexible enhancements

- Reduction of installation times

- Maximum flexibility as scalable to the respective need

- Domino connectors allow space savings of up to 50%

- Sustainability through consistent modularisation

Variety in sizes: from compact configurations like Modular Compact, ECO, Twin, to larger sizes (e.g. 10B, 16B, 24B, 34 HPR)

- A wide selection of hoods/housings: panel-mount, cable-to-cable, carrier hoods, etc.

- Locking mechanisms: screw locking, single-lever locking, snap-in latches.

- Protection ratings: available options with various IP ratings such as IP20, IP30, IP54, IP65 in both mated and unmated conditions.

- Multiple cable entry options: single, integrated, or various threaded entries (e.g. M20, M25, M

Han Modular 70Amp 1500V Module

The HARTING Han® Modular 70A 1500V Crimp Module is a high-performance solution designed for demanding high-voltage applications. Rated for up to 70 A and 1500 V, this module features an enhanced design with significantly longer clearance and creepage distances, achieved with only a minimal increase in length compared to previous models. This improvement allows for higher working voltages while maintaining compatibility with existing 70A modules.

The HARTING Han® Modular 70A 1500V Crimp Module is a high-performance solution designed for demanding high-voltage applications. Rated for up to 70 A and 1500 V, this module features an enhanced design with significantly longer clearance and creepage distances, achieved with only a minimal increase in length compared to previous models. This improvement allows for higher working voltages while maintaining compatibility with existing 70A modules.

Features & Benefits:

- Increased creepage/clearance

- Voltage Increase to 1500V

- Insulated Cap on Contacts

- No contact to live conductive parts

- Expanded area of use in the same footprint

- Increased safety for operator

Power 16 300A Module

Harting’s Power 16 … 300 A Han-Modular® connectors are part of the Han-Modular® system, designed for high-current industrial applications. These double-module inserts provide robust power transmission up to 300 A and can be combined with other Han® modules for signal, data, or additional power within a single connector frame. They are available in crimp and busbar versions, giving engineers flexibility depending on cable or distribution needs. The crimp variant is suited for large cable terminations, while the short busbar version is optimized for robust power distribution setups. Both deliver high reliability and safety in demanding environments, making them a strong choice for industries that require compact yet powerful modular connector solutions.

Features & Benefits:

Rated Current: 300 A

Rated Voltage: 1,000 V AC / 1,300 V DC, with impulse voltage up to 8 kV

Termination Methods: Crimp with axial screw termination (female version) or screw termination for busbar (male version)

Number of Contacts: Single-contact, double-module design

Conductor Range: 70 – 120 mm² (for crimp versions)

Operating Temperature: –40 °C to +125 °C

Durability: At least 500 mating cycles

Materials: Polycarbonate housing (RAL 7032 pebble grey), UL 94 V-0 flame retardant

Compliance & Safety: Meets EN 50124-1, IEC 60664-1, IEC 61984, and UL 1977 standards; certified for railway fire protection (EN 45545-2, HL1–3)

RoHS, REACH, and Proposition 65 compliant

Han-Modular Surge Protection Module

HARTING has developed a protective circuit housed within a modular connector in order to protect common signals in the instrumentation and control (I&C) area. This means that both digital and analogue circuits are securely protected. Since these signals can be of different types, in addition to a modular combination for I&C signals with common reference potential (generally digital signals), HARTING also offers a combination for differential signal transmission or for transmission without a common reference signal.

HARTING has developed a protective circuit housed within a modular connector in order to protect common signals in the instrumentation and control (I&C) area. This means that both digital and analogue circuits are securely protected. Since these signals can be of different types, in addition to a modular combination for I&C signals with common reference potential (generally digital signals), HARTING also offers a combination for differential signal transmission or for transmission without a common reference signal.

These signals are generally differential types such as bus interfaces up to 5 MHz or analogue signals such as 0/4-20 mA or 0/2-10 V. Both types – two-channel types for differential signals and four-channel types for signals with common reference potential – can transmit nominal 24 V DC and up to 0.5 A. The protection level is approximately 50 V, depending on the type.

Features & Benefits:

- Operationg Voltage: 24VDC/0.5A

- Less wiring minimizes space for design

- No crosstalk to other signals

- Overvoltage stops at the cabinet wall

- Plug and Play/Connect and Protect

- IP20

Han-Modular® docking frames

Han® Modular Docking Frames are accessory frames designed to hold and align multiple Han-Modular insert modules within a single rectangular connector interface. These modular frames allow for a flexible, custom mix of signal, power, or data modules—perfect for tailored industrial connectivity solutions.

Han® Modular Docking Frames are accessory frames designed to hold and align multiple Han-Modular insert modules within a single rectangular connector interface. These modular frames allow for a flexible, custom mix of signal, power, or data modules—perfect for tailored industrial connectivity solutions.

Key Features & Benefits:

- Flexible Configuration – Available in various sizes (2, 3, 4, or 6 module slots), and options for float-mount or fixed-mount frames allow for tailored assembly according to project needs.

- Float Mounting for Alignment Tolerance – Offers ±2 mm of alignment tolerance, easing installation & accommodating slight misalignments—ideal for dynamic or modular systems.

- Durable zinc die-cast material, these frames withstand harsh industrial environments, with temperature ratings from –40 °C to +125 °C and support over 10,000 mating cycles.

- Compatible with nearly all Han® Modular modules—except Megabit, RJ45, optical, and pneumatic modules—providing versatile integration of power, signal, and communication elements.

- Application-Focused Design – Commonly used in applications like energy storage systems for rack-mounted modules, facilitating pre-assembly, quick maintenance, and minimized downtime.

- Designed per IEC standards (IEC 60664-1, IEC 61984), these docking frames support high voltage (≤ 630 V, impulse voltage ≤ 6 kV) and maintain performance across industrial conditions

Harting’s Industrial Circular Connectors (ICC) are a versatile family of rugged, high-performance connectors designed to deliver reliable signal, power, and data transmission in harsh industrial environments. Built to withstand shock, vibration, dust, moisture, and extreme temperatures, these connectors are commonly used in machinery, robotics, automation, energy, and transportation applications. Circular Connectors Brochure

Harting’s Industrial Circular Connectors (ICC) are a versatile family of rugged, high-performance connectors designed to deliver reliable signal, power, and data transmission in harsh industrial environments. Built to withstand shock, vibration, dust, moisture, and extreme temperatures, these connectors are commonly used in machinery, robotics, automation, energy, and transportation applications. Circular Connectors Brochure

- Panel Feed Throughs – Designed to integrate seamlessly into enclosure walls or control panels. They provide a reliable and secure connection between internal and external components. Whether they are used in control cabinets, machines or devices, our round wall bushings ensure robust performance and efficient signal transmission.

- PCB Connectors – Provide a direct connection between a device’s PCBs and it’s environment. These connectors ensure efficient data, power and signal exchange and stands for very reliable connectivity in your electronic designs.

- Cable Connectors & Assemblies – Play a crucial role in connecting cables to devices or control cabinets. They offer a versatile solution for connecting power, signals or data. Our cable connectors are designed for durability, ease of installation and optimum performance. Each of HARTING’s connectors is available with the matching cable. These plug & play cable assembly solutions avoid wiring errors and reduces downtime.

- See ICC Connector Series in Action

ICC 20 Series

Scalable, industrial circular connectors excelling in harsh environments

The ICC 20 4/3 delivers up to 40A with integrated signal contacts, combining Han® C and Han D® technology for robotics and automation. The new Single Pole version transmits up to 400A/600V for energy-intensive applications like heavy-load robot arms, welding, and mobile machinery. With IP67/IP69 protection, EMC shielding, and support for multiple insulators and interfaces—including SPE, USB, and RJ45—the ICC 20 series offers versatile, compact, and future-ready solutions for power, signal, and data transmission in harsh industrial environments.

The ICC 20 4/3 delivers up to 40A with integrated signal contacts, combining Han® C and Han D® technology for robotics and automation. The new Single Pole version transmits up to 400A/600V for energy-intensive applications like heavy-load robot arms, welding, and mobile machinery. With IP67/IP69 protection, EMC shielding, and support for multiple insulators and interfaces—including SPE, USB, and RJ45—the ICC 20 series offers versatile, compact, and future-ready solutions for power, signal, and data transmission in harsh industrial environments.

Features & Benefits:

High scalability due to the integration of Han® 3 A inserts (approximately 50 in total)

Durability thanks to robust design, vibration resistance and high IP67/69 protection ratings

Space savings of up to 20 % for individual interfaces

Up to 50 % higher output up to > 400A in the same installation space

Convenient installation and touch-safe contacts

See ICC Connector Series in Action

ICC20 EMC Backshell

Harting is pleased to introduce the extension of the Installation Circular Connector series with new variants of backshells for the ICC size 20. These EMC backshells as well as the new backshell with M32 internal threads opens access to new applications and support the flexible ICC series approach.

Harting is pleased to introduce the extension of the Installation Circular Connector series with new variants of backshells for the ICC size 20. These EMC backshells as well as the new backshell with M32 internal threads opens access to new applications and support the flexible ICC series approach.

Features & Benefits:

- EMC Spring

- Flexible ICC Series approach

- Allows for termination of the shield at the gland

- 360 shielding

ICC20 4/3 Insert

HARTING expands its Installation Circular Connector (ICC) series with the size 20 4/3 insert, designed to accommodate both power and signal connections within a single compact unit. This innovative insert supports power contacts rated up to 40 A and signal contacts up to 10 A, catering to a wide range of industrial applications. The insert is engineered for seamless integration with existing ICC series housings, featuring a bayonet locking mechanism that ensures secure and reliable connections. The flexible housing concept, combined with familiar contact technology and straightforward coding, enhances user convenience during installation and maintenance. Constructed from robust materials, the Size 20 4/3 insert is built to withstand demanding operational environments, making it suitable for industries such as machinery, energy, and transportation.

HARTING expands its Installation Circular Connector (ICC) series with the size 20 4/3 insert, designed to accommodate both power and signal connections within a single compact unit. This innovative insert supports power contacts rated up to 40 A and signal contacts up to 10 A, catering to a wide range of industrial applications. The insert is engineered for seamless integration with existing ICC series housings, featuring a bayonet locking mechanism that ensures secure and reliable connections. The flexible housing concept, combined with familiar contact technology and straightforward coding, enhances user convenience during installation and maintenance. Constructed from robust materials, the Size 20 4/3 insert is built to withstand demanding operational environments, making it suitable for industries such as machinery, energy, and transportation.

Features & Benefits:

- Circular form factor

- Ability to utilize ICC shell

- Space efficient as compared to similar solutions

- Power and signal pins

- Hybrid solution reducing the number of connectors needed

- Cost and space efficiency

PushPull Circular Connectors

HARTING’s PushPull connector series offers fast, secure, and tool-free connections for industrial environments, making it ideal for high-demand applications such as factory automation, robotics, and machine engineering. These connectors are designed to transmit power, data, and signals in a compact form factor—ensuring reliability even in harsh conditions. The PushPull series simplifies maintenance, reduces installation time, and ensures secure connections under vibration or frequent mating cycles. It’s especially valuable in decentralized control systems and outdoor or mobile machinery.

simplifies maintenance, reduces installation time, and ensures secure connections under vibration or frequent mating cycles. It’s especially valuable in decentralized control systems and outdoor or mobile machinery.

Key Features:

- Tool-free locking: Quick and secure connections via an intuitive push-pull mechanism—just click to connect or disconnect.

- IP65/IP67 protection: Resistant to dust, water, and harsh environments, making them ideal for field installations.

- Power, signal & data in one: Available in versions supporting power (up to 16A), signal, and high-speed Ethernet (Cat. 6A, up to 10 Gbit/s)

- Modular interface: Compatible with various device interfaces and customizable for different applications.

- Space-saving design: Compact form factors suitable for tight installation spaces.

- Cross-platform compatibility: Meets IEC 61076 standards and available in multiple styles (V4 Industrial, V4 Hybrid, V4 Data, etc.).

The Big Brother

Modularity has long been a core principle in robotic system design, where tools and end-effectors must be quickly reconfigured to suit varying operational requirements. In automotive manufacturing environments, HARTING’s PushPull Variant 14—an advanced counterpart to the PushPull V4—proves particularly advantageous. Engineered with robust zinc die-cast housings, these connectors endure extreme mechanical stress, provide effective electromagnetic shielding (EMC), and resist welding spatter encountered in vehicle body assembly lines. When a robot’s function must shift, hard-wired solutions are impractical. The PushPull V14 enables rapid, tool-free reconfiguration, offering a consistent, reliable interface. Its adaptable design supports a wide range of transmission media—including Ethernet, signal, power, and fiber optics—making it ideal for long-distance, high-performance robotic applications.

Modularity has long been a core principle in robotic system design, where tools and end-effectors must be quickly reconfigured to suit varying operational requirements. In automotive manufacturing environments, HARTING’s PushPull Variant 14—an advanced counterpart to the PushPull V4—proves particularly advantageous. Engineered with robust zinc die-cast housings, these connectors endure extreme mechanical stress, provide effective electromagnetic shielding (EMC), and resist welding spatter encountered in vehicle body assembly lines. When a robot’s function must shift, hard-wired solutions are impractical. The PushPull V14 enables rapid, tool-free reconfiguration, offering a consistent, reliable interface. Its adaptable design supports a wide range of transmission media—including Ethernet, signal, power, and fiber optics—making it ideal for long-distance, high-performance robotic applications.

The Strong Third

To simplify power supply connections, HARTING offers the PushPull Power L version. Featuring a rugged zinc die-cast housing, it delivers excellent protection against harsh environmental conditions and mechanical impact. Like the V4 and V14 variants, it enables fast, tool-free mating and disconnection. Designed to handle up to 16A at 24V, it’s well-suited for high-demand power applications. Its AIDA compliance highlights its suitability for automotive robotics environments. One click—and power is reliably delivered.

To simplify power supply connections, HARTING offers the PushPull Power L version. Featuring a rugged zinc die-cast housing, it delivers excellent protection against harsh environmental conditions and mechanical impact. Like the V4 and V14 variants, it enables fast, tool-free mating and disconnection. Designed to handle up to 16A at 24V, it’s well-suited for high-demand power applications. Its AIDA compliance highlights its suitability for automotive robotics environments. One click—and power is reliably delivered.

7/8 " Metric Circular Connectors

7/8″ Circular Connectors

Harting’s 7/8″ circular connectors are rugged power connectors designed for industrial environments. With screw-locking for secure mating, IP65/IP67 protection, and HARAX® quick-connect options, they provide reliable power and signal connections for drives, sensors, actuators, and fieldbus systems.

Harting’s 7/8″ circular connectors are rugged power connectors designed for industrial environments. With screw-locking for secure mating, IP65/IP67 protection, and HARAX® quick-connect options, they provide reliable power and signal connections for drives, sensors, actuators, and fieldbus systems.

Features & Benefits:

Available in 3-, 4-, and 5-pole versions

Rated up to 10 A per contact (0.75–1.5 mm² conductors)

IP65/IP67 environmental protection

Screw-locking (7/8″ UN 16 standard)

Field-attachable, overmoulded cable, and panel-mount styles

HARAX® quick-connection—tool-free, solderless installation

M8 Metric Circular Connectors

M8 CIRCULAR CONNECTORS

HARTING’s M8 circular connectors are compact, robust solutions designed for space-constrained applications in industrial automation, transportation, and sensor/actuator systems. Engineered for reliable signal and data transmission, these connectors are ideal for field-level connectivity where durability and performance are critical.

Key Features:

Compact Design: Small form factor makes them ideal for tight installation spaces, such as sensors, actuators, and control cabinets.

Compact Design: Small form factor makes them ideal for tight installation spaces, such as sensors, actuators, and control cabinets.Versatile Interfaces: Available for signal and data transmission, with versions supporting analog and digital signals as well as Ethernet protocols.

Field Assembly Options: Offered in pre-assembled versions and field-terminable models with screw, IDC, or HARAX® quick-connection technology—no special tools needed.

Rugged Construction: Designed with IP65/IP67-rated housings for reliable performance in harsh, dusty, or wet environments.

Electrical Specs: Supports 2A to 4A rated current and up to 60V rated voltage, depending on the model.

Coding Options: Available with A-coding (typically for signal) and B-, D-, or L-coding options for specialized applications.

Straight & Angled Versions: Provides flexibility in installation, available in both male and female configurations.

Standards Compliant: Conforms to IEC 61076-2-104 for industry-wide compatibility and reliability.

M12 Metric Circular Connectors

M12 Circular Connectors

M12 circular connectors are a standard interface widely adopted across industrial automation for power, signal, and high-speed data transmission. Offered in multiple codings (A, B, D, X, etc.), they ensure protocol-specific compatibility across control, sensor, and Ethernet systems. Engineered with IP65/67 ingress protection and robust metal housings, M12 connectors maintain electrical integrity and mechanical reliability in high-vibration, moisture-prone environments.

M12 circular connectors are a standard interface widely adopted across industrial automation for power, signal, and high-speed data transmission. Offered in multiple codings (A, B, D, X, etc.), they ensure protocol-specific compatibility across control, sensor, and Ethernet systems. Engineered with IP65/67 ingress protection and robust metal housings, M12 connectors maintain electrical integrity and mechanical reliability in high-vibration, moisture-prone environments.

Key Features:

- Signals (A, B coding), 2 – 12 poles

- Data (D, X coding), 4 and 8 poles

- Power (L, S, K coding) 3 and 4 poles + FE/PE, up to 16 A / 630 V

- Hybrid (Y coding) 4 + 4 poles for data and power

- Configurator for customised cable assemblies

Resources:

M23 Metric circular Connectors

M23 Circular Connectors

HARTING’s M23 circular connectors are designed for high-performance industrial applications where robust, multi-signal connections are essential. These connectors are widely used in automation, robotics, machinery, and drive systems, offering a compact yet powerful interface for transmitting power, signals, and data—often all in one connector.

Key Features:

High Power Handling: Supports up to 28A and 630V, making them ideal for motors, drives, and other energy-intensive devices.

High Power Handling: Supports up to 28A and 630V, making them ideal for motors, drives, and other energy-intensive devices.Signal & Data Integration: Available in hybrid versions to transmit power, signal, and data through a single connector—simplifying cabling and reducing installation time.

Versatile Configurations: Offered in straight and angled variants with a wide range of contact arrangements (6 to 19+ contacts) for flexible system integration.

Rugged Protection: IP67/IP69K-rated housings resist dust, water, and harsh environmental conditions; available in plastic or metal shells depending on application needs.

Reliable Locking System: Secure screw-lock or quick-lock mechanisms ensure vibration-resistant connections in dynamic or mobile applications.

Field Assemblable: Termination styles include crimp, solder, or pre-assembled cable versions for flexible installation and maintenance.

Standards Compliant: Conforms to IEC standards, ensuring compatibility with other M23 systems across various industries.

EMC Shielding: Options with 360° shielding for electromagnetic compatibility, critical in environments with high electrical noise.

Han® Ex for Explosion Hazardous Enviroments

Han® Ex connectors are heavy-duty, intrinsically safe rectangular connectors created to operate safely in explosion-hazardous environments (Zones 1 & 2 for gas and Zones 21 & 22 for dust) by restricting energy to levels that prevent ignition.

Han® Ex connectors are heavy-duty, intrinsically safe rectangular connectors created to operate safely in explosion-hazardous environments (Zones 1 & 2 for gas and Zones 21 & 22 for dust) by restricting energy to levels that prevent ignition.

Features & Benefits:

Intrinsically Safe (“Ex i”) Protection – Designed to limit voltage, current, capacitance, and inductance—ensuring that, even under fault conditions, sparks cannot ignite explosive atmospheres.

International Explosion Zone Certification – Suitable for use in hazardous zones: Zone 1 & 2 (gas) and Zone 21 & 22 (dust), per ATEX/IEC standards.

Visual Safety Coding – Blue-colored hoods and housings make it easy to identify intrinsically safe connectors.

Robust & Reliable Design – Achieves IP65/IP67 environmental protection when mated. Hoods & housings are made from zinc die-cast alloy, featuring stainless steel locking levers that require tools to disengage—protecting against accidental openings.

High-Density Inserts – Compact inserts accommodate a large number of contacts—typically between 4 to 24, sometimes more—supporting efficient power & signal transmission in limited space.

Flexible Termination Options – Choose between crimp, screw, or Han-Quick Lock® (tool-free) termination methods for fast, secure, and vibration-resistant connections.

Tailored Sets for Varied Needs – Available in complete sets comprising hoods, housings, and inserts—with configurations ranging from 3 to 12 contacts, covering power and signal.