Industrial & Robotics – Manufacturing Equipment

Maximize uptime. Simplify integration. Future-proof your factory.

HARTING delivers robust and intelligent connectivity solutions engineered for today’s fast-paced and data-driven manufacturing environments. From power and signal to high-speed Ethernet and IIoT integration, HARTING products are trusted by OEMs and system integrators to keep machines running reliably—no matter how harsh the environment or how complex the system.

Whether you’re designing industrial automation controls, motion systems, or smart production lines, HARTING offers a wide range of connectors, cables, and edge computing technologies that support seamless operation, efficient maintenance, and scalable expansion.

- Industrial Automation & Control Systems

- Semiconductor Manufacturing Equipment

- Robotics & Motion Control

- Packaging Machinery

- Machine Tools & CNC Equipment

- Material Handling & Conveying Systems

- Control Cabinets & Panels

- Smart Manufacturing & IIoT Integration

- Test, Measurement & QA Systems

- Limited Space in Machines and Control Panels – Modern industrial equipment is becoming more compact, requiring miniaturized yet robust connectors that can deliver full performance in tight spaces.

- High-Speed Data Transmission & IIoT Readiness – Industrial automation increasingly relies on fast, reliable data for real-time control, monitoring, and smart manufacturing integration.

- Harsh Industrial Environments (Vibration, Dust, Moisture) – Connectors must withstand shock, vibration, dust, oil, and moisture typical of factory floors.

- Power and Signal Hybridization – Modern equipment often requires both power and signal/data connections in the same interface to reduce cabling and simplify installation.

- Industry 4.0 and Modular Machine Design – Equipment must be modular, upgradeable, and compatible with digital factory infrastructures.

- Fast Installation & Maintenance

Industrial Automation & Control Systems: HARTING connectors power and connect PLCs, I/O modules, and distributed control systems. Modular interfaces like Han-Modular® and har-flex® ensure reliable electrical and data transmission in panel or field-mounted components.

Semiconductor Manufacturing Equipment: The effectiveness of your semiconductor manufacturing equipment relies on dependable connectivity, for power, data, and/or signal relays. With a broad range of connectivity solutions, you’ll be sure to find what you need for the designs of today and innovations of tomorrow.

Robotics & Motion Control: High-performance hybrid connectors support servo drives, encoders, and robotic arms, delivering both power and signal in compact, vibration-resistant formats.

Packaging Machinery: HARTING solutions streamline integration into labeling, filling, sealing, and wrapping systems with lightweight, tool-free Han-Eco® connectors and flexible cable assemblies.

Machine Tools & CNC Equipment: For lathes, milling machines, and automated tool systems, HARTING provides rugged, EMI-resistant connectors like the Han® HPR series, ideal for environments with high mechanical stress.

Material Handling & Conveying Systems: Modular power/data interfaces and RFID solutions ensure efficient, traceable movement across conveyors, sorters, and AGVs, supporting flexible logistics and automation.

Control Cabinets & Panels: From compact board-level connections to panel feed-throughs, HARTING simplifies wiring inside electrical enclosures while enhancing system reliability and maintainability.

Smart Manufacturing & IIoT Integration: With products like the MICA® edge computer and T1 Industrial Single Pair Ethernet connectors, HARTING enables real-time monitoring, predictive maintenance, and seamless connectivity between machines and the cloud.

Test, Measurement & QA Systems: HARTING offers shielded connectors and custom cable assemblies that support consistent, interference-free data collection and inspection in manufacturing test environments.

Featured Product Solutions

Miniaturized connector for 4-8 wire Ethernet and Power over Ethernet (PoE) capabilities.

Until recently, the gold standard for Ethernet interfaces in IP20 environments has been the RJ45 connector. As the most widely used connector worldwide, it has earned popularity among users. However, it also comes with frustrations—its delicate locking tabs and occasional contact issues have led to mixed feelings. As devices such as slim mobile units, compact displays, automation equipment, cameras, and sensors continue to shrink in size, the RJ45 becomes a limiting factor for miniaturization. Users and developers alike have been seeking a smaller, more robust alternative that also delivers Cat. 6A performance for 1/10 Gbit/s Ethernet at the control level. HARTING’s ix Industrial® system answers this call with a compact, high-performance interface. Enter Captain ix—the embodiment of the HARTING ix Industrial® Ethernet solution—designed to transform the landscape of IoT and industrial Ethernet. Mission accomplished: the ix Industrial® is now officially recognized as an industry standard (IEC 61076-3-124), providing a reliable and space-saving option for device manufacturers and a true alternative to the RJ45.

Until recently, the gold standard for Ethernet interfaces in IP20 environments has been the RJ45 connector. As the most widely used connector worldwide, it has earned popularity among users. However, it also comes with frustrations—its delicate locking tabs and occasional contact issues have led to mixed feelings. As devices such as slim mobile units, compact displays, automation equipment, cameras, and sensors continue to shrink in size, the RJ45 becomes a limiting factor for miniaturization. Users and developers alike have been seeking a smaller, more robust alternative that also delivers Cat. 6A performance for 1/10 Gbit/s Ethernet at the control level. HARTING’s ix Industrial® system answers this call with a compact, high-performance interface. Enter Captain ix—the embodiment of the HARTING ix Industrial® Ethernet solution—designed to transform the landscape of IoT and industrial Ethernet. Mission accomplished: the ix Industrial® is now officially recognized as an industry standard (IEC 61076-3-124), providing a reliable and space-saving option for device manufacturers and a true alternative to the RJ45.

iX Industrial® PushPull IP20 Connector

The next evolution of compact Ethernet connectivity, the HARTING ix Industrial® PushPull IP20 enhances the proven performance of the ix Industrial® interface with tool-free, secure PushPull mating. It supports Cat. 6A Class EA transmission up to 10 Gbit/s and features a robust, overmolded cable outlet for superior bend protection and tension resistance. With an audible click for reliable mating, 5,000 mating cycles, and a compact, space-saving design, it’s ideal for control cabinets, robotics, and handheld devices—where speed, reliability, and ruggedness matter most.

The next evolution of compact Ethernet connectivity, the HARTING ix Industrial® PushPull IP20 enhances the proven performance of the ix Industrial® interface with tool-free, secure PushPull mating. It supports Cat. 6A Class EA transmission up to 10 Gbit/s and features a robust, overmolded cable outlet for superior bend protection and tension resistance. With an audible click for reliable mating, 5,000 mating cycles, and a compact, space-saving design, it’s ideal for control cabinets, robotics, and handheld devices—where speed, reliability, and ruggedness matter most.

iX Industrial Type A and Type B

Type A

– designed for high-speed Ethernet and data transmission applications in industrial environments. Supporting Category 6A performance up to 10 Gbps, Type A features a 10-position interface—eight for data and two reserved for future functionality. With a rugged metal snap-in locking mechanism and compact size (70% smaller than a standard RJ45), it provides a secure, space-saving solution for industrial switches, routers, controllers, and other networked devices. Compliant with IEC 61076-3-124, Type A also supports Power over Ethernet (PoE/PoE+), making it ideal for demanding Industry 4.0 and IIoT systems.

Type B –

Builds on the same compact and rugged platform as Type A but with a different pinout designed for hybrid signal and power transmission. It also features a 10-position design and is suited for factory automation, control cabinets, and device-level interconnects where combining power and data into one interface is advantageous. Type B retains the secure snap-in locking, high EMC shielding, and 5,000 mating cycle durability, making it an excellent choice for robust, multifunctional industrial applications.

iX Industrial Type-C Connectors

Type C connector is a streamlined version focused purely on high-performance data transmission. With an 8-position configuration dedicated exclusively to Ethernet connectivity, it supports up to Cat. 6A performance (10 Gbps) without additional reserved contacts for power or auxiliary signals. Type C is built with the same rugged, miniaturized housing and locking system as Types A and B, offering excellent resistance to vibration and mechanical stress. Its compact footprint makes it ideal for industrial automation, robotics, and embedded systems where only data communication is required and space is at a premium.

Type C connector is a streamlined version focused purely on high-performance data transmission. With an 8-position configuration dedicated exclusively to Ethernet connectivity, it supports up to Cat. 6A performance (10 Gbps) without additional reserved contacts for power or auxiliary signals. Type C is built with the same rugged, miniaturized housing and locking system as Types A and B, offering excellent resistance to vibration and mechanical stress. Its compact footprint makes it ideal for industrial automation, robotics, and embedded systems where only data communication is required and space is at a premium.

Quick and easy handling, robustness, flexibility in use, a long life cycle and, ideally, a tool-free assembly – whatever you expect from a connector – Han® rectangular connectors and industrial circular connectors won’t disappoint you. You’ll get even more.

- Industrial Circular Connectors – For applications with limited space or dedicated installation or assembly specifications that only permit a circular connector, HARTING is offering a broad range of industrial circular solutions.

- Rectangular Connectors – Quick and easy handling, robustness, flexibility in use, a long life cycle and, ideally, a tool-free assembly – whatever you expect from a connector – Han® rectangular connectors won’t disappoint you. You’ll get even more.

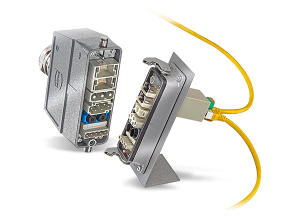

Han-Modular®

The market standard for modular industrial connectors

Han® rectangular connectors are the industry benchmark for robust industrial connections, enabling the modular design of machinery and systems. Engineered to perform in harsh environments, they ensure reliable, pluggable transmission of power, signals, and data—meeting the highest standards of industrial applications. A standout in the portfolio, the Han-Modular® series allows users to combine power, data, and signal in a single connector. With more than 100 different modules available, the system accommodates various transmission media and termination techniques, including advanced data solutions like the Han-Quintax® (Cat 5), Han Megabit Module (2 x Cat 5), and Han Gigabit Module (Cat 6A and Cat 8.2). Its patented hinged frame enables flexible configuration of modules within the trusted Han® hoods and housings, offering modular, compact, and lightweight connectivity for demanding sectors such as machinery, transportation, energy, automotive, and device integration.

Han® rectangular connectors are the industry benchmark for robust industrial connections, enabling the modular design of machinery and systems. Engineered to perform in harsh environments, they ensure reliable, pluggable transmission of power, signals, and data—meeting the highest standards of industrial applications. A standout in the portfolio, the Han-Modular® series allows users to combine power, data, and signal in a single connector. With more than 100 different modules available, the system accommodates various transmission media and termination techniques, including advanced data solutions like the Han-Quintax® (Cat 5), Han Megabit Module (2 x Cat 5), and Han Gigabit Module (Cat 6A and Cat 8.2). Its patented hinged frame enables flexible configuration of modules within the trusted Han® hoods and housings, offering modular, compact, and lightweight connectivity for demanding sectors such as machinery, transportation, energy, automotive, and device integration.

- Integration of multiple connectors into a single unit

- Shorter installation times

- Cost savings on system and components

- Significant reduction in space requirements

- Future-proof/flexible enhancements

- Harting’s Configurator

Han-Modular® Domino

An innovative expansion of the Han-Modular® platform, designed to further optimize space, weight, and flexibility in industrial connector configurations. It allows users to split standard Han-Modular® modules into smaller, cube-like “Domino” modules, effectively doubling the customization potential within the same connector footprint.

An innovative expansion of the Han-Modular® platform, designed to further optimize space, weight, and flexibility in industrial connector configurations. It allows users to split standard Han-Modular® modules into smaller, cube-like “Domino” modules, effectively doubling the customization potential within the same connector footprint.

- Maximized connector utilization (no wasted module space)

- Reduced connector size and panel cutouts

- Lightweight solution for mobile or modular equipment

- Fewer connectors needed per machine/system

Han® 1A – Compact, robust and versatile

For the first time, HARTING’s Han® 1A offers a compact, affordable connector, which can be used for controllers, small drives and control cabinets, and can also be installed in the field. Within this very compact and cost-optimised product family HARTING offers now M12 D-coded and M12 X-coded inserts for different application fields.

For the first time, HARTING’s Han® 1A offers a compact, affordable connector, which can be used for controllers, small drives and control cabinets, and can also be installed in the field. Within this very compact and cost-optimised product family HARTING offers now M12 D-coded and M12 X-coded inserts for different application fields.

- Smallest Han® connector: Up to 30% smaller than the Han® 3 A

- Versatile use: Transmission of data, signals and power

- Very flexible: Modular system for IP20 and IP65 applications

- Faster installation: Fast connection using snap-in technology

- Reduced costs: Affordable installation connector

- Han 1A Connector System Video

- Han 1A Connector Guide

All Metric circular connectors share a common feature: their metric screw-locking mechanism. With their cylindrical design, circular connectors offer distinct advantages over other connector shapes, especially in specific application types. They include multiple pins or contacts that carry electrical power, signals, or data. To prevent incorrect mating, the contact interfaces are coded.

These connectors are built for durability in challenging environments, offering resistance to dust, moisture, and vibration while maintaining stable connections. Commonly used in industrial automation, transportation, and security systems, they are ideal for applications requiring frequent connection and disconnection, along with long operational lifespans.

- Panel Feed Throughs – Designed to integrate seamlessly into enclosure walls or control panels. They provide a reliable and secure connection between internal and external components. Whether they are used in control cabinets, machines or devices, our round wall bushings ensure robust performance and efficient signal transmission.

- PCB Connectors – provide a direct connection between a devices PCBs and it’s environment. They were typically chosen, where the distance of a devices inside PCB and it’s housing is close enough, for a direct PCB mount. We offer various options within this category. These connectors ensure efficient data, power and signal exchange and stands for very reliable connectivity in your electronic designs.

- Cable Connectors & Assemblies – play a crucial role in connecting cables to devices or control cabinets. They offer a versatile solution for connecting power, signals or data. Our cable connectors are designed for durability, ease of installation and optimum performance. Each of HARTING’s connectors is available with the matching cable. These plug & play cable assembly solutions avoid wiring errors and reduces downtime. Contact sales for help

M12 Circular Connectors

M12 circular connectors are a standard interface widely adopted across industrial automation for power, signal, and high-speed data transmission. Offered in multiple codings (A, B, D, X, etc.), they ensure protocol-specific compatibility across control, sensor, and Ethernet systems. Engineered with IP65/67 ingress protection and robust metal housings, M12 connectors maintain electrical integrity and mechanical reliability in high-vibration, moisture-prone environments.

M12 circular connectors are a standard interface widely adopted across industrial automation for power, signal, and high-speed data transmission. Offered in multiple codings (A, B, D, X, etc.), they ensure protocol-specific compatibility across control, sensor, and Ethernet systems. Engineered with IP65/67 ingress protection and robust metal housings, M12 connectors maintain electrical integrity and mechanical reliability in high-vibration, moisture-prone environments.

Key Features:

- Signals (A, B coding), 2 – 12 poles

- Data (D, X coding), 4 and 8 poles

- Power (L, S, K coding) 3 and 4 poles + FE/PE, up to 16 A / 630 V

- Hybrid (Y coding) 4 + 4 poles for data and power

- Configurator for customised cable assemblies

Resources:

M8 CIRCULAR CONNECTORS

HARTING’s M8 circular connectors are compact, robust solutions designed for space-constrained applications in industrial automation, transportation, and sensor/actuator systems. Engineered for reliable signal and data transmission, these connectors are ideal for field-level connectivity where durability and performance are critical.

Key Features:

Compact Design: Small form factor makes them ideal for tight installation spaces, such as sensors, actuators, and control cabinets.

Versatile Interfaces: Available for signal and data transmission, with versions supporting analog and digital signals as well as Ethernet protocols.

Field Assembly Options: Offered in pre-assembled versions and field-terminable models with screw, IDC, or HARAX® quick-connection technology—no special tools needed.

Rugged Construction: Designed with IP65/IP67-rated housings for reliable performance in harsh, dusty, or wet environments.

Electrical Specs: Supports 2A to 4A rated current and up to 60V rated voltage, depending on the model.

Coding Options: Available with A-coding (typically for signal) and B-, D-, or L-coding options for specialized applications.

Straight & Angled Versions: Provides flexibility in installation, available in both male and female configurations.

Standards Compliant: Conforms to IEC 61076-2-104 for industry-wide compatibility and reliability.

M23 Circular Connectors

HARTING’s M23 circular connectors are designed for high-performance industrial applications where robust, multi-signal connections are essential. These connectors are widely used in automation, robotics, machinery, and drive systems, offering a compact yet powerful interface for transmitting power, signals, and data—often all in one connector.

Key Features:

High Power Handling: Supports up to 28A and 630V, making them ideal for motors, drives, and other energy-intensive devices.

High Power Handling: Supports up to 28A and 630V, making them ideal for motors, drives, and other energy-intensive devices.Signal & Data Integration: Available in hybrid versions to transmit power, signal, and data through a single connector—simplifying cabling and reducing installation time.

Versatile Configurations: Offered in straight and angled variants with a wide range of contact arrangements (6 to 19+ contacts) for flexible system integration.

Rugged Protection: IP67/IP69K-rated housings resist dust, water, and harsh environmental conditions; available in plastic or metal shells depending on application needs.

Reliable Locking System: Secure screw-lock or quick-lock mechanisms ensure vibration-resistant connections in dynamic or mobile applications.

Field Assemblable: Termination styles include crimp, solder, or pre-assembled cable versions for flexible installation and maintenance.

Standards Compliant: Conforms to IEC standards, ensuring compatibility with other M23 systems across various industries.

EMC Shielding: Options with 360° shielding for electromagnetic compatibility, critical in environments with high electrical noise.

Wide range of robust PCB connectors with 1.27mm pitch in pin counts from 6-100

The drive toward Industry 4.0 demands solutions that are simultaneously compact, high performance, and mechanically robust. The harflex® PCB connector series meets these requirements with a miniaturized form factor and high modularity, enabling engineers to implement scalable, board-to-board and cable-to-board interconnects optimized for limited-space applications. Supporting signal integrity, high-speed data transmission, and reliable power delivery, har-flex® connectors are available in a variety of form factors, termination styles, and pin counts—making them ideal for densely populated PCBs and demanding embedded systems.

Key Features:

- Options for power, signal and hybrid connectors

- Featuring diverse designs

- Featuring diverse pole counts

- Many mating cycles and reliable contacts

- High speed up to 25 Gbit/s

- Ready for Industry: SMT and THR hold-downs

In addition to the standard har-flex® in 1.27 mm pitch, the har-flex® product family also offers connectors with 2.54 mm pitch. har-flex® Power was specifically designed for the transmission of high currents between 18 A and 29 A.

The flexible pole numbers from 2 to 12 are made possible by a modular manufacturing concept. Moreover, users can choose between SMT and THR power contact versions. har-flex® Power PCB connectors are available in straight and angled design and can be used in parallel (mezzanine) board, extender card and motherboard-to-daughtercard configurations.

A special feature of the har-flex® PCB connector family and the modular manufacturing concept is the combination of signal and power contacts: the birth of the har-flex® Hybrid. This makes compact and versatile connection solutions possible, which are ideal for miniaturized PCB systems.

A special feature of the har-flex® PCB connector family and the modular manufacturing concept is the combination of signal and power contacts: the birth of the har-flex® Hybrid. This makes compact and versatile connection solutions possible, which are ideal for miniaturized PCB systems.

har-flex® Hybrid connectors are available in straight and angled versions and can be used in parallel (mezzanine) board, extender card and motherboard-to-daughtercard configurations.

The familiar har-flex® PCB connector with the proven 1.27 mm pitch is ideal for miniaturized industrial applications. Pole numbers from 6 to 100 in steps of 2, paired with a wide variety of straight and angled designs and IDC cable connection versions result in a diverse range of possibilities. Customers can implement new and smaller systems without compromising robustness.

The familiar har-flex® PCB connector with the proven 1.27 mm pitch is ideal for miniaturized industrial applications. Pole numbers from 6 to 100 in steps of 2, paired with a wide variety of straight and angled designs and IDC cable connection versions result in a diverse range of possibilities. Customers can implement new and smaller systems without compromising robustness.

Customized versions are possible on request. The trend is increasingly moving away from standardized rack solutions towards modularized devices which require miniaturized and customized PCB arrangements.

Single Pair Ethernet (SPE) enables cost-efficient Ethernet connectivity across all areas of industrial automation, using just a single pair of wires to transmit data at speeds up to 1 Gbit/s. This makes it an ideal solution for Industry 4.0 and IIoT applications. Standardized under IEC 63171-6, the HARTING T1 Industrial interface sets the benchmark for industrial SPE connectivity. Its optimized high-frequency performance, robust shielding, and mechanical durability make it the ideal choice to meet the demanding requirements of industrial Ethernet environments.

Single Pair Ethernet (SPE) enables cost-efficient Ethernet connectivity across all areas of industrial automation, using just a single pair of wires to transmit data at speeds up to 1 Gbit/s. This makes it an ideal solution for Industry 4.0 and IIoT applications. Standardized under IEC 63171-6, the HARTING T1 Industrial interface sets the benchmark for industrial SPE connectivity. Its optimized high-frequency performance, robust shielding, and mechanical durability make it the ideal choice to meet the demanding requirements of industrial Ethernet environments.

Features & Benefits:

- Only 2 wires to communicate Ethernet provides significant weight and diameter reduction of the cable

- Symmetrical design of the mating interface allows highly optimized high frequency transmission performance

- Up to 1,000m reach with 10 Mbit/s data performance and PoDL (Power over Data Line) functionality

- Ability to deliver data and power over very long distances to devices residing at the edge of the industrial networks

- 60V DC voltage rating

- Current rating: 4A at 60DC, 1.5A at 85C

- -40 to 85 degrees C operating temp

For decades, D-Sub connectors—short for D-subminiature—have been a trusted solution for transmitting bus signals in industrial environments. HARTING’s D-Sub series builds on this legacy with rugged, high-performance designs engineered for reliable signal and data transmission in harsh conditions. Available in a wide range of pole configurations, housings, contact types, and variants—including standard, high-density, mixed, filtered, and IP-rated versions—HARTING D-Subs offer the versatility needed to meet the demands of automation and robotics applications.

For decades, D-Sub connectors—short for D-subminiature—have been a trusted solution for transmitting bus signals in industrial environments. HARTING’s D-Sub series builds on this legacy with rugged, high-performance designs engineered for reliable signal and data transmission in harsh conditions. Available in a wide range of pole configurations, housings, contact types, and variants—including standard, high-density, mixed, filtered, and IP-rated versions—HARTING D-Subs offer the versatility needed to meet the demands of automation and robotics applications.

Features & Benefits:

A versatile range of products: – D-Sub Standard, D-Sub High Density, D-Sub Mixed, D-Sub Filter, D-Sub Waterproof, D-Sub THR, D-Sub SMT

For wave and reflow soldering – through hole technology, surface mount technology and through hole reflow

Modular connector for the PCB D-Sub Mixed

Speedy installation in a modern production process helps to reduce costs

Very versatile and customer-friendly

German Innovation Award 2021 Winner!

HARTING’s har-modular® is a highly customizable, board-to-board connector system designed to give engineers complete design freedom. What makes har-modular® special is its modularity—users can configure their own connectors online by selecting from over a billion possible combinations of power, signal, and data modules.

HARTING’s har-modular® is a highly customizable, board-to-board connector system designed to give engineers complete design freedom. What makes har-modular® special is its modularity—users can configure their own connectors online by selecting from over a billion possible combinations of power, signal, and data modules.

Key Features:

- Modular design: Choose and combine power (up to 16A), signal (up to 25 contacts), and data (up to 10 Gbit/s) modules in one connector.

High performance: Supports a wide range of voltage, current, and transmission speed requirements.

Tailor-made solutions: Configure connectors to exact application needs without tooling or lengthy lead times.

Scalable and reusable: Easily adapted for future changes in design or system requirements.

Tool-free configuration: Online configurator simplifies selection and ordering.

Standard PCB pitch: 1.27 mm pitch ensures compatibility with standard PCB layouts.

har-modular® is especially valuable for prototyping, small-series production, and applications where space, performance, and flexibility are critical—such as in test equipment, embedded computing, and custom industrial electronics.

Resources:

HARTING’s PushPull connector series offers fast, secure, and tool-free connections for industrial environments, making it ideal for high-demand applications such as factory automation, robotics, and machine engineering. These connectors are designed to transmit power, data, and signals in a compact form factor—ensuring reliability even in harsh conditions.

The PushPull series simplifies maintenance, reduces installation time, and ensures secure connections under vibration or frequent mating cycles. It’s especially valuable in decentralized control systems and outdoor or mobile machinery.

simplifies maintenance, reduces installation time, and ensures secure connections under vibration or frequent mating cycles. It’s especially valuable in decentralized control systems and outdoor or mobile machinery.

Key Features:

- Tool-free locking: Quick and secure connections via an intuitive push-pull mechanism—just click to connect or disconnect.

- IP65/IP67 protection: Resistant to dust, water, and harsh environments, making them ideal for field installations.

- Power, signal & data in one: Available in versions supporting power (up to 16A), signal, and high-speed Ethernet (Cat. 6A, up to 10 Gbit/s)

- Modular interface: Compatible with various device interfaces and customizable for different applications.

- Space-saving design: Compact form factors suitable for tight installation spaces.

- Cross-platform compatibility: Meets IEC 61076 standards and available in multiple styles (V4 Industrial, V4 Hybrid, V4 Data, etc.).

The Big Brother

Modularity has long been a core principle in robotic system design, where tools and end-effectors must be quickly reconfigured to suit varying operational requirements. In automotive manufacturing environments, HARTING’s PushPull Variant 14—an advanced counterpart to the PushPull V4—proves particularly advantageous. Engineered with robust zinc die-cast housings, these connectors endure extreme mechanical stress, provide effective electromagnetic shielding (EMC), and resist welding spatter encountered in vehicle body assembly lines. When a robot’s function must shift, hard-wired solutions are impractical. The PushPull V14 enables rapid, tool-free reconfiguration, offering a consistent, reliable interface. Its adaptable design supports a wide range of transmission media—including Ethernet, signal, power, and fiber optics—making it ideal for long-distance, high-performance robotic applications.

Modularity has long been a core principle in robotic system design, where tools and end-effectors must be quickly reconfigured to suit varying operational requirements. In automotive manufacturing environments, HARTING’s PushPull Variant 14—an advanced counterpart to the PushPull V4—proves particularly advantageous. Engineered with robust zinc die-cast housings, these connectors endure extreme mechanical stress, provide effective electromagnetic shielding (EMC), and resist welding spatter encountered in vehicle body assembly lines. When a robot’s function must shift, hard-wired solutions are impractical. The PushPull V14 enables rapid, tool-free reconfiguration, offering a consistent, reliable interface. Its adaptable design supports a wide range of transmission media—including Ethernet, signal, power, and fiber optics—making it ideal for long-distance, high-performance robotic applications.

–

The Strong Third

To simplify power supply connections, HARTING offers the PushPull Power L version. Featuring a rugged zinc die-cast housing, it delivers excellent protection against harsh environmental conditions and mechanical impact. Like the V4 and V14 variants, it enables fast, tool-free mating and disconnection. Designed to handle up to 16A at 24V, it’s well-suited for high-demand power applications. Its AIDA compliance highlights its suitability for automotive robotics environments. One click—and power is reliably delivered.

To simplify power supply connections, HARTING offers the PushPull Power L version. Featuring a rugged zinc die-cast housing, it delivers excellent protection against harsh environmental conditions and mechanical impact. Like the V4 and V14 variants, it enables fast, tool-free mating and disconnection. Designed to handle up to 16A at 24V, it’s well-suited for high-demand power applications. Its AIDA compliance highlights its suitability for automotive robotics environments. One click—and power is reliably delivered.

Featured Videos

Playlist

0:16

Additional Resources

New Product Announcements

- HARTING Han E PCB/PIT Contacts for Han EE

- HARTING UIC IT Connector

- HARTING Mini PushPull ix Industrial AWG22-24

- HARTING Circular Connector ICC20 EMC Backshell

- HARTING Han Modular 70AMP 1500V Module

- HARTING Mini PushPull T1 Industrial Connector

- HARTING ix Industrial Type C Connectors

- HARTING Han HPR Single Pole Connectors

- HARTING ix Industrial In-Line Cable Jack

- HARTING M12 Push-in L-code Connectors